Other Projects

Bobcat Uranium Project

Highlights

The Shirley Basin was the site of the first commercial ISR project in the United States

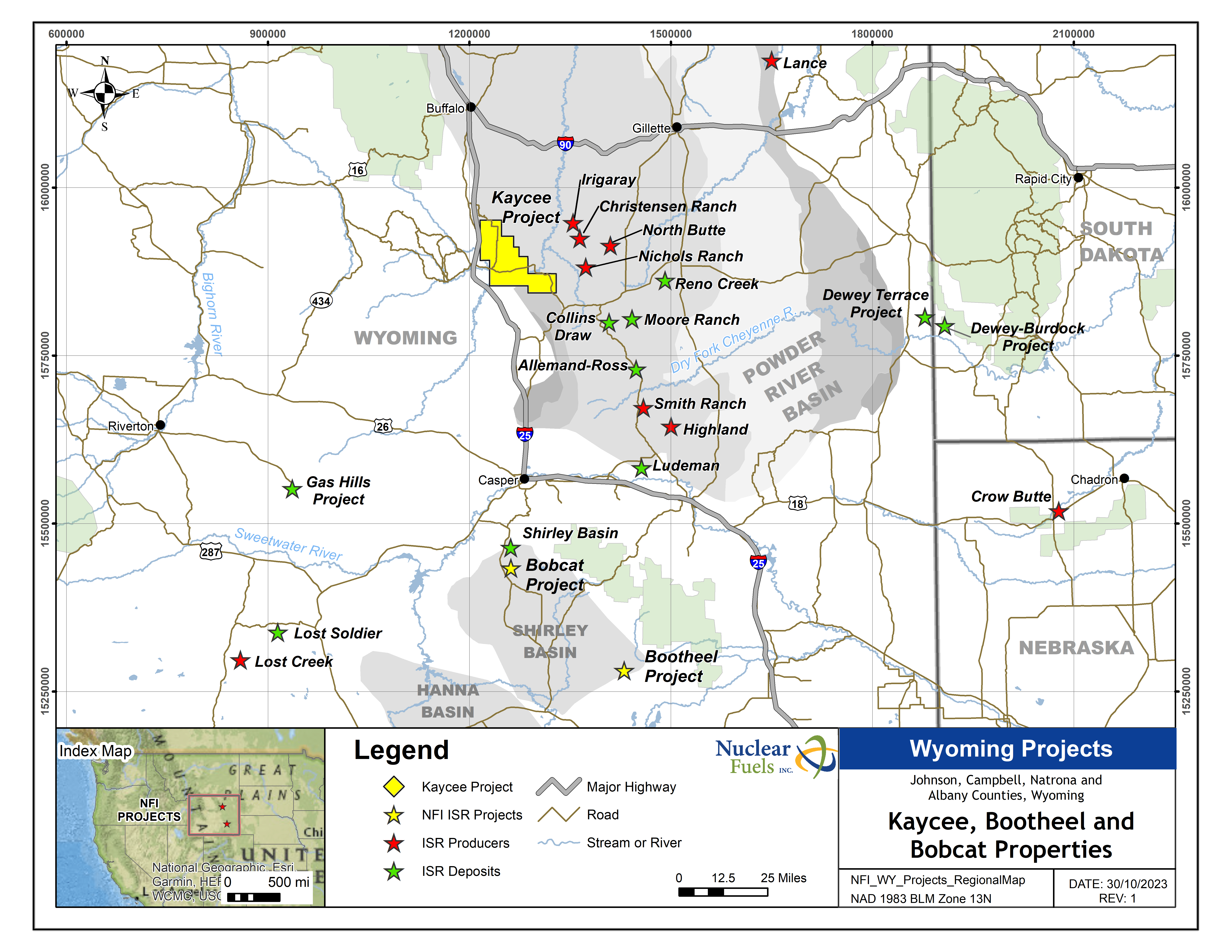

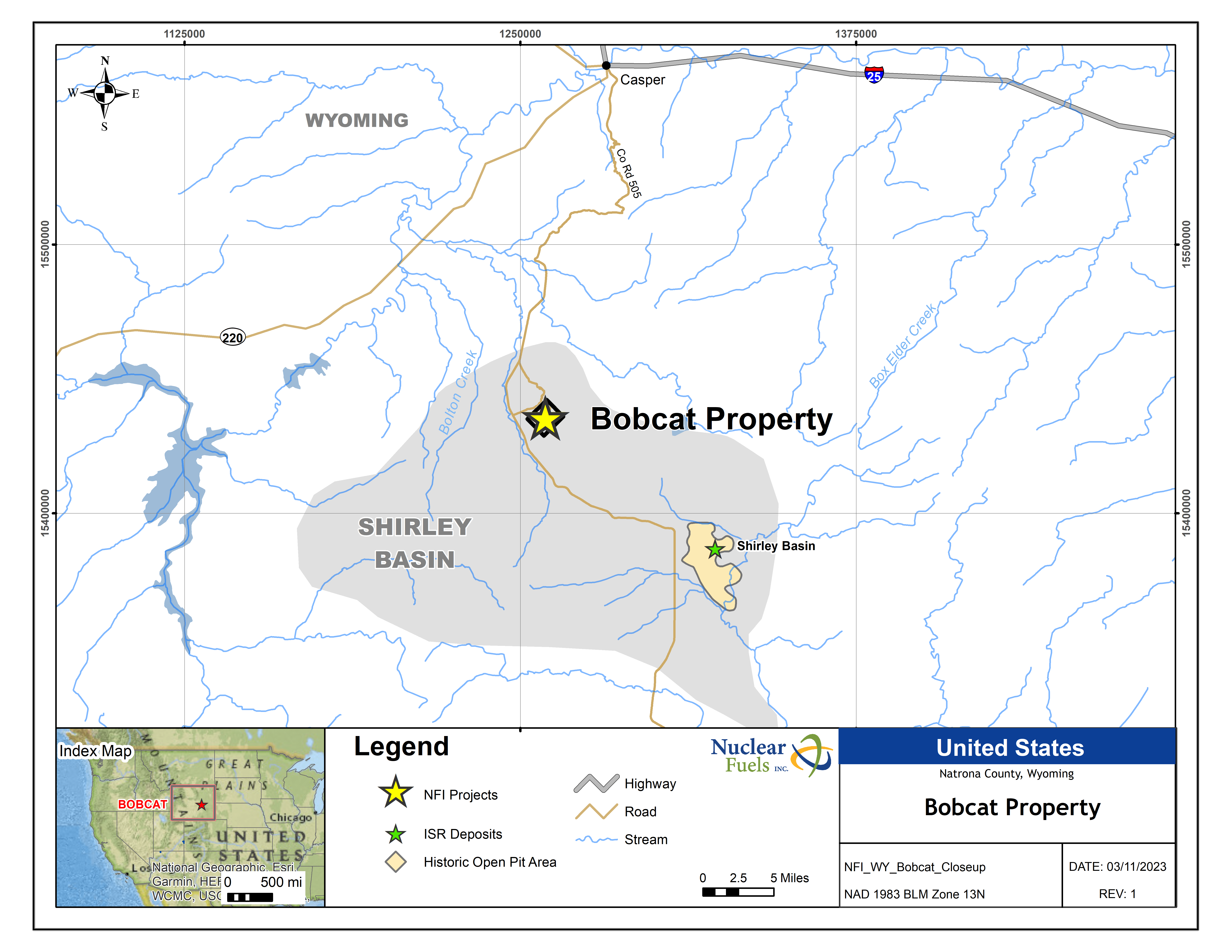

Located 25 miles south of Casper Wyoming in Albany County, the Bobcat Project is located in the Shirley Basin. The Shirley Basin was a proven and prolific producer of uranium credited with over 84 million lbs. produced between 1959 and 1992 from producers including Getty Oil Company, Texaco, Inc., Pathfinder Mines Corporation, Cogema Mining Inc., Although the majority of the district’s production has come from conventional mining, in 1964 the Shirley Basin was home to the first commercial use of the In-Situ Recovery (“ISR”) technique to extract uranium from sandstone-host deposits. ISR is now utilized to extract over 60% of all uranium in the world; since the 1990s all uranium mining in Wyoming has used the ISR process.

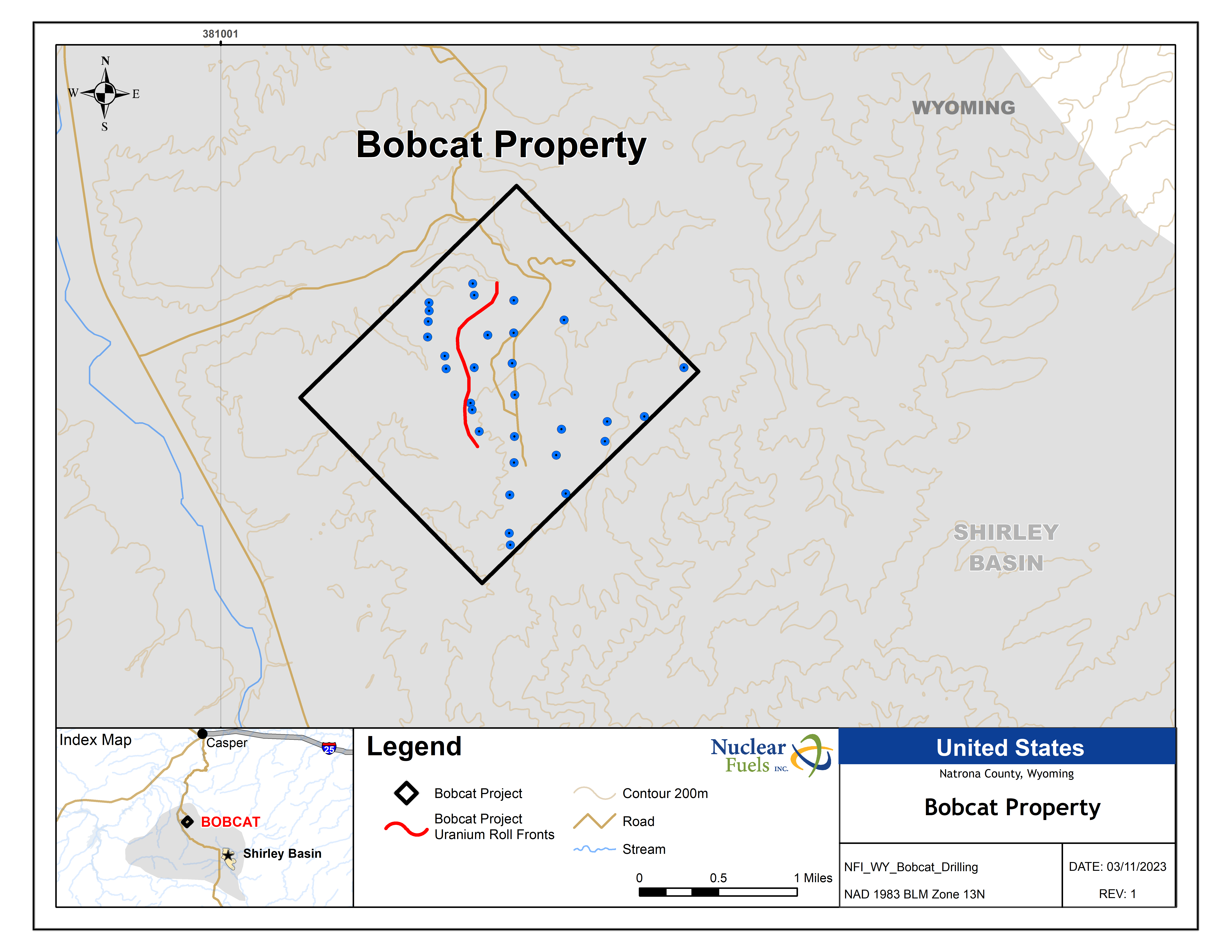

The Bobcat Project was originally explored by Western Resources and joint venture partners in the 1970’s and early 1980’s where it was one of the last uranium projects they continued to hold in the face of low uranium prices. With our more than 1,600 acres of mineral rights, the Bobcat Project covers a mineralized roll front and is open to expansion.

*Readers are cautioned that a qualified person has not done sufficient work to classify any of the historical estimates as current mineral resources or mineral reserves as defined by NI 43-101. The Company is not treating the historical estimates as current mineral resources or reserves as defined by NI 43-101 but it forms a basis for further exploration. Further compilation of the historic geological and drilling data, resource modelling and additional drilling will be necessary to convert the historic estimates outlined above to NI 43- 101 conforming mineral resources. The historical estimate does not use the current mineral resources categories prescribed under NI 43-101.The historic resource is based on information from Western Standard (1972).

The technical content of this summary has been reviewed and approved by Mark Travis, CPG., a contractor to the Company, and a Qualified Person as defined in National Instrument 43-101.

More Information

The Shirley Basin is a northwest trending asymmetric basin that formed by subduction-driven Late Cretaceous to early Tertiary tectonism called the Laramide Orogeny. Laramide structuring created the basement cored uplifts that surround the basin. The basin is named for the Shirley Mountains that lie on the southwestern margin. The mountains were named after freighter John Shirley who hauled supplies to homesteaders there in the mid-1800’s (Shirley’s Mountains). The Granite Mountains (aka Sweetwater Arch) lie to the west and Bates Hole, a prominent erosional feature drained by Stinking Creek, is the north margin of the basin. The Laramie Range marks the northeastern and eastern border. Northeast-trending Flat Top anticline is the basin’s structural divide with the Laramie Basin to the south. This feature is part of the Wyoming Lineament which is a broad zone of east northeast-trending folds above a major Precambrian shear zone in central Wyoming formed during the assembly of the Wyoming Craton (Ransome,1915,Blackstone,1983).

Uranium deposits in the Eocene Wind River Formation were discovered by Teton Exploration in 1955. The leasing boom took off in 1957 with several companies acquiring leases. Utah Mining began underground mining in 1959 in the northwestern part of the district. In 1964 they converted to In-Situ Recovery (“ISR”). This was the first use of the ISR uranium mining technique in the United States. After 1968, Utah Mining began strip mining of the ore. Uranium ore was shipped to the Lucky Mc mill in the Gas Hills, 145 miles west, before an onsite mill was constructed in 1969. The mill began operations in 1971. Conventional mine operations were suspended by Pathfinder in the 1990s due to low uranium pricing.

LAB Project, Labrador

Highlights

Project Details

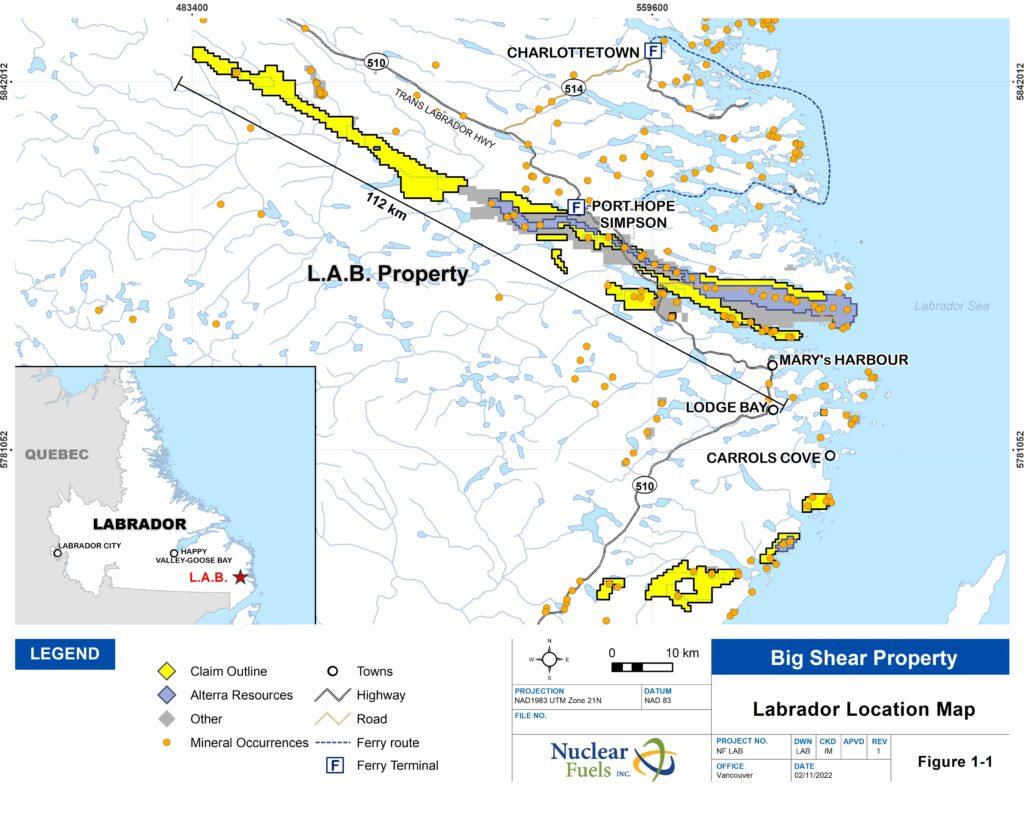

The Lab Critical Metals Project claims are adjacent to, and display similar styles of mineralization, to Search Minerals Inc’s Critical Rare Earth Metals Project claims. In March 2022, Search Minerals published a Preliminary Economic Assessment on their Critical Rare Earth Metals Project.

*Exploration results on adjacent projects and geologically similar projects are not necessarily indicative of the mineral potential of Nuclear Fuels’ claims. the company’s Labrador Critical Metals project is under an 100% option agreement and subject to a 3% NSR with a 1.5% buyback with a third party.

The technical content of this technical summary has been reviewed and approved by Michael Collins, P.Geo., (BC Permit #1003770 and PEGNL), an officer of the Company, and a Qualified Person as defined in National Instrument 43-101.

Lisbon Valley Project

The Lisbon Valley project has two claim blocks; the LS and JB mining claims, totaling 107 claims covering approximately 2,211 acres (895 hectares) in the Lisbon Valley Uranium District, southeastern Utah.

The Lisbon Valley District is in the Colorado Plateau region, 30 miles southeast of Moab, Utah. The Lisbon Valley District was a center of historic conventional surface and underground mining uranium production from 1948 to 1988 of approximately 78 million pounds U3O8. The uranium mineralization in the Lisbon Valley district is primarily hosted by the Moss Back Member of the lower Chinle Formation of Triassic age. The Moss Back sandstone has the unique distinction of hosting some of the highest-grade uranium and vanadium mineralization in the Colorado Plateau region.

The LS claim group is located just southeast and adjacent to the Lisbon mine, on the downthrown side of the Lisbon Valley anticline. The Lisbon mine was owned and operated by Rio Algom Mines Ltd., with production between 1972 to 1988, producing approximately 22 million pounds U3O8 from the Moss Back sandstone. Drilling on the LS claims in 2007 reported* intersecting significant uranium mineralization amounting to 17.5 feet grading 0.11 per cent U3O8 (including 3.5 feet grading 0.28 per cent U3O8) in drill hole L-15, collard about 8,000 feet southeast of the Lisbon mine. The claims are subject to a 2-per-cent net smelter royalty.

*Reported in a press release dated Sept. 10, 2007, Mesa Uranium Corp. this drilling is historical in nature and a qualified person has not done sufficient work to verify historic drilling. Additional work will be required to verify and update the historical work.

The technical content of this summary has been reviewed and approved by Mark Travis, CPG., a contractor to the Company, and a Qualified Person as defined in National Instrument 43-101.